Environment and Energy

Energy use

- Green electricity 49%

- Electricity from own generation 1.5%

- Natural gas 45%

- Diesel 3.5%

- Petrol 1%

Let the sun shine:

more self-generated electricity

BPW has also been using hydropower since the company was founded in 1898 – originally to power a hammer mill and most recently for power generation. However, it was necessary to stop turbine operation in 2018 due to technical inspections and planned renovation work. It will also be out of action in 2019. Internal energy production is therefore expected to fall to 770,000 kWh.

INTERNALLY PRODUCED ELECTRICITY IN kWh

2016

2017

2018

Carbon offsetting: switchover to eco-friendly gas by 2020

Diesel is out, electric drives are in: including in the BPW fleet

BPW continued converting its fleet in 2018. The new vehicles it purchases mainly have electric or hybrid drives, or – if there is no economically viable electric alternative – petrol engines. To enable them to charge up with enough power, BPW has already installed 17 charging stations for electric vehicles at its three sites in the Oberbergischer Kreis district.

- Diesel 100%

- electric 0%

- Diesel 89%

- electric 11%

- Diesel 78%

- electric 22%

- Diesel/Petrol 98%

- electric/hybrid 2%

- Diesel/Petrol 85%

- electric/hybrid 15%

- Diesel/Petrol 83%

- electric/hybrid 17%

CO2 emissions dramatically reduced

2016

Tons CO2

2017

Tons CO2

2018

Tons CO2

Saving energy is the best way to protect the climate

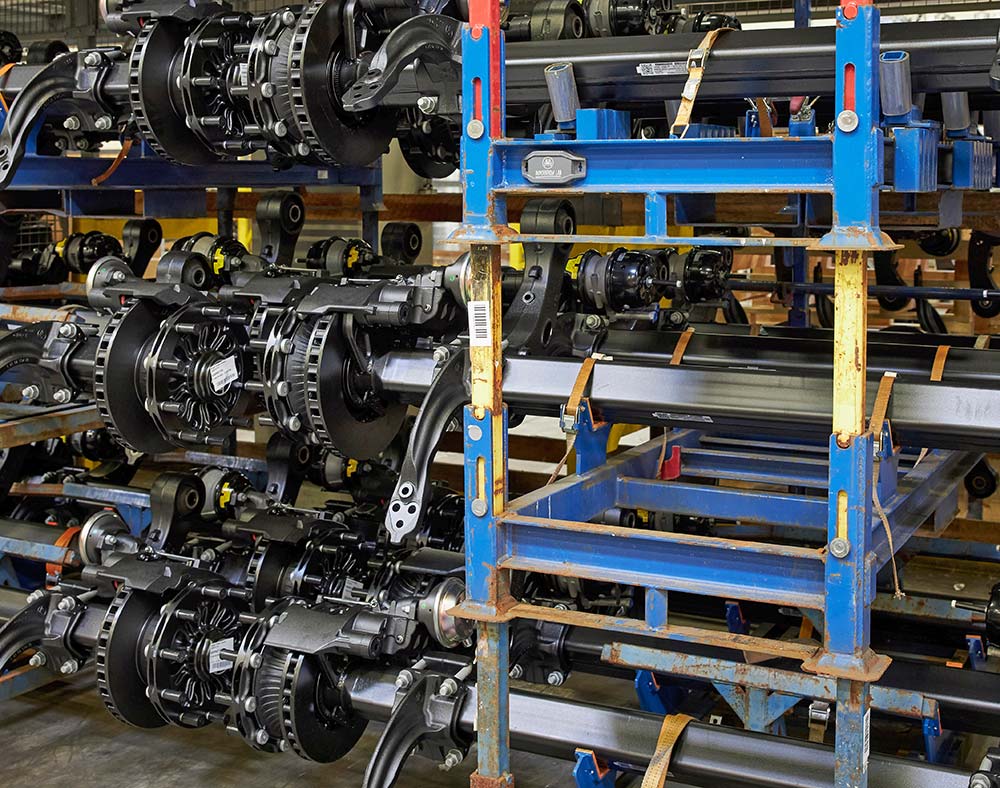

BPW was able to save over 500,000 kWh in 2018 thanks to investment in new production systems, modernisation and the demolition of energy-intensive buildings. This kept the energy usage per axle system to 175 kWh. BPW is aiming for an overall reduction of 1 million kWh in 2019. This is an ambitious target as the increasing mechanisation and automation of production can drive energy usage up just as much as it can reduce it in some places.

An energy officer coordinates, monitors and documents the success of the measures – but working towards efficient use of energy and resources is something that every employee and manager must do.

- 2016: 189,3 kWh 100%

- 2017: 174,0 kWh 95%

- 2018: 175,0 kWh 92%

BPW Bergische Achsen KG is committed to:

On the lookout for wasted energy

They learnt the practical basics in workshops and then started their own project on energy saving in order to develop suggestions for improvement. The four young scouts are in the third year of their apprenticeships and are undertaking training in marketing communication, industrial mechanics or cutting machinery. Their project and the final assignment based on this will automatically enter them into a competition.

CO2-efficient logistics

‘The hauliers LKW Walter and OLS have already introduced environmental management and also use rail, waterways and combined transport when moving goods for BPW. This enabled BPW to save more than 29,000 kg of CO2 in 2018 – and we want to systematically expand this success in future with binding selection criteria for logistics partners.’

Fred Krämer, Head of Dispatch Logistics at BPW

Sustainable packaging

Clean on the way in and on the way out: just 1% drinking water consumption

However, the seemingly sudden drop in water use in 2018 was caused by the need to shut down and renovate the hydropower turbine.

2016

m³

2017

m³

2018

m³

Sorted: waste management at BPW

However, the volume of waste and the recycling rate are still subject to strong fluctuations due to one-off effects, including demolition and construction work and one-off disposal due to process changeovers, as well as new legal requirements for recycling. Significant successes in the reduction of process waste may also be reflected in the statistics for lower recycling rates.

2016

%

recycling rate in total

Tons

1596 t non-hazardous waste

489 t hazardous waste

2017

%

recycling rate in total

Tons

1170 t non-hazardous waste

480 t hazardous waste

2018

%

recycling rate in total

Tons

2437 t non-hazardous waste

569 t hazardous waste

Swarm intelligence

‘Bees and insects are short on food these days. BPW is doing its bit to preserve biodiversity with these patches of land. However, there is a lack of rain, which means that we often can’t water the plants to compensate for the dryness.’

Frank Ammann, Gardener at BPW

The highest standards for the environment, climate and conservation of resources

BPW’s environmental management system was certified in April 2018 in accordance with the comprehensive global standard DIN EN ISO 140001:2015. At the same time, the BPW energy management system was certified in accordance with the latest version of DIN EN ISO 50001:2011. By constantly investing in new state-of-the-art systems, the company is continuously improving its energy efficiency and will further improve its energy-related performance. BPW is already meeting the requirements for environmental and energy management – and so the company is striving for even more ambitious targets. BPW plans to gain certification in accordance with ISO 50001:2018 in April 2020.